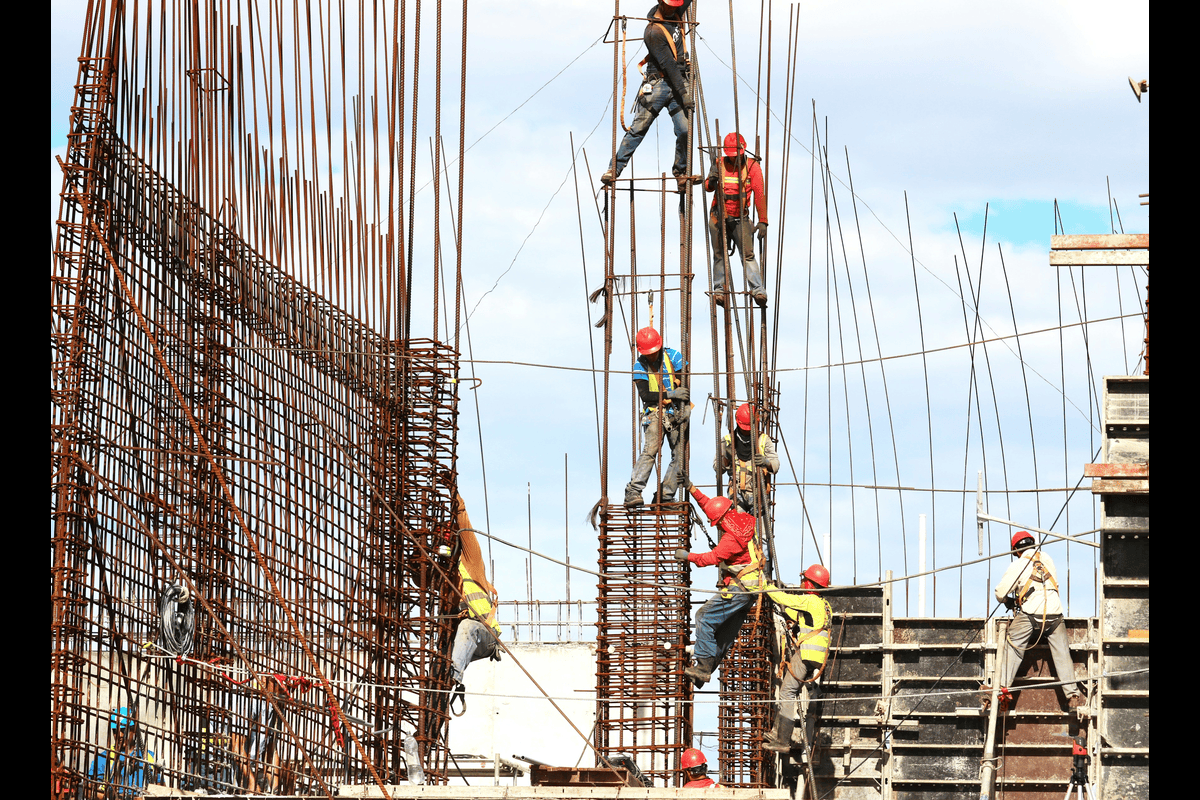

By prioritizing precision and coordination, organizations can remodel how assets are managed. Waste reduction becomes practicable at the same time as making plans, shifting from guesswork to Construction websites generate enormous cloth waste at the same time as making plans that are wrong or incomplete. Excess ordering, terrible coordination, and format misinterpretations frequently result in unused materials piling up on the website. This will not only influence outstanding growth mission prices but also influence environmental sustainability and beneficial resource performance.

Smarter amount planning lets contractors align procurement with real task needs. When materials are carefully measured and scheduled by Construction Estimating Companies, advanced agencies can avoid useless surplus and decrease disposal costs. This technique, moreover, improves workflow due to the fact that crews gather precisely what they need at the right time.

Modern production more and more focuses on ordinary overall performance, responsibility, and sustainability. Better making plans guarantees projects stay on track, rate variability is maintained, timelines are robust, and environmental impact is minimized. A hooked-up method enables smoother operations at the same time as strengthening collaboration among contractors, estimators, and carriers.

knowledgeable choice-making supported by the resource of experience and statistics.

Understanding Waste Challenges on Modern Jobsites

Material waste remains virtually one of the most important hidden expenses in production initiatives. Incorrect measurements, over-ordering, and unexpected layout modifications often bring about leftover substances that cannot be reused effectively.

Many contractors underestimate how small mistakes accumulate. A mild miscalculation, repeated sooner or later, of multiple additives can bring about massive waste. Transportation harm, garage issues, and lowering losses further make a contribution to fabric inefficiencies.

Professionals deal with those annoying conditions by way of reading every stage of the task lifecycle. They do not forget internet website conditions, layout complexity, and execution timelines to ensure substances are used efficiently and responsibly.

How Accurate Planning Improves Resource Utilization

Smart planning ensures that materials are added in accurate quantities and used in step with the undertaking’s desires. This reduces clutter on the internet webpage and allows teams to work more efficiently without coping with vain stock.

When belongings are optimized, responsibilities benefit from reduced fees, better productivity, and superior protection. Workers can focus on setting up in preference to handling greater material, which complements regular performance.

A mounted system like lumber takeoff allows for determining actual portions required for structural components, minimizing overordering, and helping with better project coordination.

The Connection Between Budget Control and Waste Reduction

Financial stability in the advent relies heavily on cloth performance. Waste no longer best will boom procurement prices; however furthermore provides expenses related to storage, dealing with, and disposal. Accurately making plans allows contractors to estimate charges more effectively and maintain control over spending. When quantities are aligned with actual necessities, budgeting becomes extra reliable and obvious.

This technique permits mission managers to allocate property strategically, making sure rate variety is used so that the highest rate is achieved in order to avoid being out of place in preventable waste.

Improving Procurement Strategies for Better Outcomes

Procurement performs an essential role in reducing jobsite waste. Ordering materials without proper planning frequently results in surplus stock that stays unused or becomes broken over time.

Strategic shopping for choices makes certain that materials are brought in keeping with task tiers, decreasing annoying garage situations and handling dangers. Teams can coordinate deliveries with setup schedules to improve overall performance.

Many contractors rely upon Construction Estimating Services to create correct cost forecasts and align procurement choices with assignment timelines, ensuring minimum waste and maximum productivity.

Technology’s Role in Smarter Material Planning

Digital gadgets have transformed the introduction of planning with the aid of the usage of imparting correct measurements, real-time updates, and higher visualization of material requirements. Software answers assist in discovering inconsistencies earlier than they turn out to be expensive mistakes.

Automation allows groups to identify music usage styles and understand regions wherein waste normally occurs. This statistics-pushed technique allows non-preventive improvement and allows groups to refine planning techniques over the years.

Collaboration structures, moreover, make sure all stakeholders have proper access to the same records, reducing misunderstandings and preventing vain cloth orders.

Professional Expertise and Long-Term Efficiency

Experience has a high characteristic in minimizing waste. Skilled specialists recognize a way to interpret designs, count on fabric losses, and plan for contingencies that could rise up in the direction of execution.

Working with a reliable construction estimation company gives contractors expert insights and proven techniques for reinforcing planning accuracy. This results in ordinary aid management and higher venture results.

Long-term periods of usual overall performance are achieved while companies implement standardized planning processes and put money into education, generation, and collaboration.

Sustainable Practices Through Smarter Planning

Environmental obligation is turning into an issue in modern manufacturing. Reducing cloth waste contributes directly to sustainability dreams and lowers the environmental footprint of initiatives.

Efficient planning encourages recycling, reuse, and responsible disposal practices. It additionally supports using green materials and optimized decreasing strategies that reduce leftover portions.

As sustainability becomes a competitive benefit, businesses that prioritize smarter planning will stand out for their willpower to achieve accountable production.

Final Thoughts

Reducing jobsite waste requires a proactive technique based on accuracy, collaboration, and strategic planning. Smarter quantity planning, supported by a Construction Estimating Service, guarantees substances are used successfully, charges are controlled, and responsibilities progress easily without pointless disruptions.

When contractors shift from reactive preference-making to established planning, they benefit from greater management over assets and timelines. This no longer simply improves productivity but, moreover, strengthens relationships with customers and stakeholders.

The future of creation depends on overall performance and sustainability. Companies that focus on precision, generation, and professional information are probably better prepared to govern assets responsibly and deliver fulfillment duties with minimum waste.

FAQs

Why does jobsite waste occur in introduction projects?

Waste regularly results from misguided planning, over-ordering, layout modifications, and poor coordination amongst teams responsible for procurement and execution.

How can smarter planning reduce waste?

It ensures accurate measurements, better scheduling, and the right procurement, which prevents more ordering and improves resource usage.

Does waste discount decorate mission budgets?

Yes, lowering waste lowers procurement, storage, and disposal fees, supporting projects that live within financial limits.

What function does technology play in minimizing waste?

Digital gear offers unique calculations, tracks usage patterns, and permits real-time updates, which facilitates preventing mistakes and overordering.

Is sustainable advent associated with cloth planning?

Absolutely. Efficient planning reduces environmental effect via minimizing extra substances and promoting recycling and responsible usage.